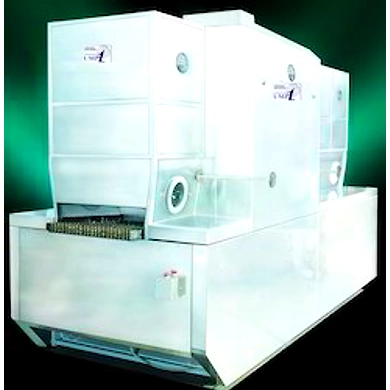

Sterilizing Tunnel

SKU124

-

Product is not available

- Price upon request

-

-

Product Details: Minimum Order Quantity 1 Unit Capacity Standard Brand UniPack We feel proud to introduce ourselves as the leading manufacturers, exporters, distributors, and suppliers of Sterilizing Tunnel. At our developing unit, we design this sterilizing tunnel as per the international standards by making use of best quality basic material and latest technology. The offered sterilizing tunnel is perfectly examined in terms of quality for ensuring their flawlessness. Along with that, customers can avail the complete assortment of sterilizing tunnel at the nominal price. Features: Dimensional accuracy Smooth finish Compact design Other Details: The vial depyrogenation tunnel will be used for depyrogenation of the vials through conventional heating system to achieve the 3 log reduction of endotoxin The exposure time for all the vials shall be more than 3 min at or above 300 when pass through the depyrogenation tunnel Vials will pass from all the 4 different zone of depyrogenation tunnel Air comes to the 4 zone of the depyrogenation tunnel will be through Hepa filters The air from drying zone and cooling zone will be exhausted out from the area and air from depyrogenation zone will be recirculated. After completion of depyrogenation operation, vials will directly transfer to the vial filling machine The vial depyrogenation tunnel operation must be performed in strict conformance with current good manufacturing practice (CGMP) Vials will come from the vial washing machine to the depyrogenation tunnel and from the depyrogenation tunnel, must be capable of interfacing with the vials washing machine and vial filling machine The vial depyrogenation tunnel control system shall include a temperature control system The control system must have the capability to display the set parameters and actual parameters Overall dimension of the machine shall match with the area layout draw The conveyor width shall match with the output requirement Depyrogenation tunnel shall have following zone Drying zone Depyrogenation zone Cooling zone Stabilizing zone The viewing port for Drying and cooling zone shall be air tight The Drying zone and cooling zone shall have EU 14 type Hepa filters Depyrogenation zone shall have you 13 type Hepa filters The machine shall have differential pressure indicator across the Help filters for the four zones Each zone or the depyrogenation tunnel shall have aerosol introduction port for the Hepa filter integrity testing Specifications: Alarm Description Interlock In adequate in feed Conveyor stop Max accumulation at out feed Conveyor stop Any of the blower fail Conveyor stop And heater off Variation of conveyor speed Conveyor stop Temperature below the set point Conveyor stop and restart after the temperature is reached. Temperature overshoot in Depyrogenation zone Heater off Turbine motor over load Conveyor + Heater + Turbine stop Differential pressure across the HEPA Conveyor stop Conveyor motor overload Conveyor stop

-

Reviews ()

Write a Review